BPI:bit板上放置了一个性能强劲的9轴传感器——MPU9250。

- 这里的9轴和空间理解的9轴不一样,其实是相当于分别的3颗3轴传感器(加速度计–Accelerator, 陀螺仪–Gyroscope,磁力计–Magnetometer)的合体。关于这个芯片的详细介绍,大家可以访问github查看文档,连接地址

代码如下

#include "quaternionFilters.h"

#include "MPU9250.h"

#ifdef LCD

#include <Adafruit_GFX.h>

#include <Adafruit_PCD8544.h>

// Using NOKIA 5110 monochrome 84 x 48 pixel display

// pin 9 - Serial clock out (SCLK)

// pin 8 - Serial data out (DIN)

// pin 7 - Data/Command select (D/C)

// pin 5 - LCD chip select (CS)

// pin 6 - LCD reset (RST)

Adafruit_PCD8544 display = Adafruit_PCD8544(9, 8, 7, 5, 6);

#endif // LCD

#define AHRS true // Set to false for basic data read

#define SerialDebug true // Set to true to get Serial output for debugging

// Pin definitions

int intPin = 12; // These can be changed, 2 and 3 are the Arduinos ext int pins

int myLed = 13; // Set up pin 13 led for toggling

MPU9250 myIMU;

void setup()

{

// TWBR = 12; // 400 kbit/sec I2C speed

Serial.begin(115200);

// Set up the interrupt pin, its set as active high, push-pull

pinMode(intPin, INPUT);

digitalWrite(intPin, LOW);

pinMode(myLed, OUTPUT);

digitalWrite(myLed, HIGH);

#ifdef LCD

display.begin(); // Ini8ialize the display

display.setContrast(58); // Set the contrast

// Start device display with ID of sensor

display.clearDisplay();

display.setTextSize(2);

display.setCursor(0, 0);

display.print("MPU9250");

display.setTextSize(1);

display.setCursor(0, 20);

display.print("9-DOF 16-bit");

display.setCursor(0, 30);

display.print("motion sensor");

display.setCursor(20, 40);

display.print("60 ug LSB");

display.display();

delay(1000);

// Set up for data display

display.setTextSize(1); // Set text size to normal, 2 is twice normal etc.

display.setTextColor(BLACK); // Set pixel color; 1 on the monochrome screen

display.clearDisplay(); // clears the screen and buffer

#endif // LCD

Wire.begin(21, 22, 100000), delay(500);

// Read the WHO_AM_I register, this is a good test of communication

byte c = myIMU.readByte(MPU9250_ADDRESS, WHO_AM_I_MPU9250);

Serial.print("MPU9250 ");

Serial.print("I AM ");

Serial.print(c, HEX);

Serial.print(" I should be ");

Serial.println(0x71, HEX);

#ifdef LCD

display.setCursor(20, 0);

display.print("MPU9250");

display.setCursor(0, 10);

display.print("I AM");

display.setCursor(0, 20);

display.print(c, HEX);

display.setCursor(0, 30);

display.print("I Should Be");

display.setCursor(0, 40);

display.print(0x71, HEX);

display.display();

delay(1000);

#endif // LCD

if (c == 0x71) // WHO_AM_I should always be 0x68

{

Serial.println("MPU9250 is online...");

// Start by performing self test and reporting values

myIMU.MPU9250SelfTest(myIMU.SelfTest);

Serial.print("x-axis self test: acceleration trim within : ");

Serial.print(myIMU.SelfTest[0], 1);

Serial.println("% of factory value");

Serial.print("y-axis self test: acceleration trim within : ");

Serial.print(myIMU.SelfTest[1], 1);

Serial.println("% of factory value");

Serial.print("z-axis self test: acceleration trim within : ");

Serial.print(myIMU.SelfTest[2], 1);

Serial.println("% of factory value");

Serial.print("x-axis self test: gyration trim within : ");

Serial.print(myIMU.SelfTest[3], 1);

Serial.println("% of factory value");

Serial.print("y-axis self test: gyration trim within : ");

Serial.print(myIMU.SelfTest[4], 1);

Serial.println("% of factory value");

Serial.print("z-axis self test: gyration trim within : ");

Serial.print(myIMU.SelfTest[5], 1);

Serial.println("% of factory value");

// Calibrate gyro and accelerometers, load biases in bias registers

myIMU.calibrateMPU9250(myIMU.gyroBias, myIMU.accelBias);

#ifdef LCD

display.clearDisplay();

display.setCursor(0, 0);

display.print("MPU9250 bias");

display.setCursor(0, 8);

display.print(" x y z ");

display.setCursor(0, 16);

display.print((int)(1000 * accelBias[0]));

display.setCursor(24, 16);

display.print((int)(1000 * accelBias[1]));

display.setCursor(48, 16);

display.print((int)(1000 * accelBias[2]));

display.setCursor(72, 16);

display.print("mg");

display.setCursor(0, 24);

display.print(myIMU.gyroBias[0], 1);

display.setCursor(24, 24);

display.print(myIMU.gyroBias[1], 1);

display.setCursor(48, 24);

display.print(myIMU.gyroBias[2], 1);

display.setCursor(66, 24);

display.print("o/s");

display.display();

delay(1000);

#endif // LCD

myIMU.initMPU9250();

// Initialize device for active mode read of acclerometer, gyroscope, and

// temperature

Serial.println("MPU9250 initialized for active data mode....");

// Read the WHO_AM_I register of the magnetometer, this is a good test of

// communication

byte d = myIMU.readByte(AK8963_ADDRESS, WHO_AM_I_AK8963);

Serial.print("AK8963 ");

Serial.print("I AM ");

Serial.print(d, HEX);

Serial.print(" I should be ");

Serial.println(0x48, HEX);

#ifdef LCD

display.clearDisplay();

display.setCursor(20, 0);

display.print("AK8963");

display.setCursor(0, 10);

display.print("I AM");

display.setCursor(0, 20);

display.print(d, HEX);

display.setCursor(0, 30);

display.print("I Should Be");

display.setCursor(0, 40);

display.print(0x48, HEX);

display.display();

delay(1000);

#endif // LCD

// Get magnetometer calibration from AK8963 ROM

myIMU.initAK8963(myIMU.magCalibration);

// Initialize device for active mode read of magnetometer

Serial.println("AK8963 initialized for active data mode....");

if (SerialDebug)

{

// Serial.println("Calibration values: ");

Serial.print("X-Axis sensitivity adjustment value ");

Serial.println(myIMU.magCalibration[0], 2);

Serial.print("Y-Axis sensitivity adjustment value ");

Serial.println(myIMU.magCalibration[1], 2);

Serial.print("Z-Axis sensitivity adjustment value ");

Serial.println(myIMU.magCalibration[2], 2);

}

#ifdef LCD

display.clearDisplay();

display.setCursor(20, 0);

display.print("AK8963");

display.setCursor(0, 10);

display.print("ASAX ");

display.setCursor(50, 10);

display.print(myIMU.magCalibration[0], 2);

display.setCursor(0, 20);

display.print("ASAY ");

display.setCursor(50, 20);

display.print(myIMU.magCalibration[1], 2);

display.setCursor(0, 30);

display.print("ASAZ ");

display.setCursor(50, 30);

display.print(myIMU.magCalibration[2], 2);

display.display();

delay(1000);

#endif // LCD

} // if (c == 0x71)

else

{

Serial.print("Could not connect to MPU9250: 0x");

Serial.println(c, HEX);

while (1)

; // Loop forever if communication doesn't happen

}

}

void loop()

{

// If intPin goes high, all data registers have new data

// On interrupt, check if data ready interrupt

if (myIMU.readByte(MPU9250_ADDRESS, INT_STATUS) & 0x01)

{

myIMU.readAccelData(myIMU.accelCount); // Read the x/y/z adc values

myIMU.getAres();

// Now we'll calculate the accleration value into actual g's

// This depends on scale being set

myIMU.ax = (float)myIMU.accelCount[0] * myIMU.aRes; // - accelBias[0];

myIMU.ay = (float)myIMU.accelCount[1] * myIMU.aRes; // - accelBias[1];

myIMU.az = (float)myIMU.accelCount[2] * myIMU.aRes; // - accelBias[2];

myIMU.readGyroData(myIMU.gyroCount); // Read the x/y/z adc values

myIMU.getGres();

// Calculate the gyro value into actual degrees per second

// This depends on scale being set

myIMU.gx = (float)myIMU.gyroCount[0] * myIMU.gRes;

myIMU.gy = (float)myIMU.gyroCount[1] * myIMU.gRes;

myIMU.gz = (float)myIMU.gyroCount[2] * myIMU.gRes;

myIMU.readMagData(myIMU.magCount); // Read the x/y/z adc values

myIMU.getMres();

// User environmental x-axis correction in milliGauss, should be

// automatically calculated

myIMU.magbias[0] = +470.;

// User environmental x-axis correction in milliGauss TODO axis??

myIMU.magbias[1] = +120.;

// User environmental x-axis correction in milliGauss

myIMU.magbias[2] = +125.;

// Calculate the magnetometer values in milliGauss

// Include factory calibration per data sheet and user environmental

// corrections

// Get actual magnetometer value, this depends on scale being set

myIMU.mx = (float)myIMU.magCount[0] * myIMU.mRes * myIMU.magCalibration[0] -

myIMU.magbias[0];

myIMU.my = (float)myIMU.magCount[1] * myIMU.mRes * myIMU.magCalibration[1] -

myIMU.magbias[1];

myIMU.mz = (float)myIMU.magCount[2] * myIMU.mRes * myIMU.magCalibration[2] -

myIMU.magbias[2];

} // if (readByte(MPU9250_ADDRESS, INT_STATUS) & 0x01)

// Must be called before updating quaternions!

myIMU.updateTime();

// Sensors x (y)-axis of the accelerometer is aligned with the y (x)-axis of

// the magnetometer; the magnetometer z-axis (+ down) is opposite to z-axis

// (+ up) of accelerometer and gyro! We have to make some allowance for this

// orientationmismatch in feeding the output to the quaternion filter. For the

// MPU-9250, we have chosen a magnetic rotation that keeps the sensor forward

// along the x-axis just like in the LSM9DS0 sensor. This rotation can be

// modified to allow any convenient orientation convention. This is ok by

// aircraft orientation standards! Pass gyro rate as rad/s

// MadgwickQuaternionUpdate(ax, ay, az, gx*PI/180.0f, gy*PI/180.0f, gz*PI/180.0f, my, mx, mz);

MahonyQuaternionUpdate(myIMU.ax, myIMU.ay, myIMU.az, myIMU.gx * DEG_TO_RAD,

myIMU.gy * DEG_TO_RAD, myIMU.gz * DEG_TO_RAD, myIMU.my,

myIMU.mx, myIMU.mz, myIMU.deltat);

if (!AHRS)

{

myIMU.delt_t = millis() - myIMU.count;

if (myIMU.delt_t > 500)

{

if (SerialDebug)

{

// Print acceleration values in milligs!

Serial.print("X-acceleration: ");

Serial.print(1000 * myIMU.ax);

Serial.println(" mg ");

Serial.print("Y-acceleration: ");

Serial.print(1000 * myIMU.ay);

Serial.println(" mg ");

Serial.print("Z-acceleration: ");

Serial.print(1000 * myIMU.az);

Serial.println(" mg ");

// Print gyro values in degree/sec

Serial.print("X-gyro rate: ");

Serial.print(myIMU.gx, 3);

Serial.println(" degrees/sec ");

Serial.print("Y-gyro rate: ");

Serial.print(myIMU.gy, 3);

Serial.println(" degrees/sec ");

Serial.print("Z-gyro rate: ");

Serial.print(myIMU.gz, 3);

Serial.println(" degrees/sec");

// Print mag values in degree/sec

Serial.print("X-mag field: ");

Serial.print(myIMU.mx);

Serial.println(" mG ");

Serial.print("Y-mag field: ");

Serial.print(myIMU.my);

Serial.println(" mG ");

Serial.print("Z-mag field: ");

Serial.print(myIMU.mz);

Serial.println(" mG");

myIMU.tempCount = myIMU.readTempData(); // Read the adc values

// Temperature in degrees Centigrade

myIMU.temperature = ((float)myIMU.tempCount) / 333.87 + 21.0;

// Print temperature in degrees Centigrade

Serial.print("Temperature is ");

Serial.print(myIMU.temperature, 1);

Serial.println(" degrees C");

}

#ifdef LCD

display.clearDisplay();

display.setCursor(0, 0);

display.print("MPU9250/AK8963");

display.setCursor(0, 8);

display.print(" x y z ");

display.setCursor(0, 16);

display.print((int)(1000 * myIMU.ax));

display.setCursor(24, 16);

display.print((int)(1000 * myIMU.ay));

display.setCursor(48, 16);

display.print((int)(1000 * myIMU.az));

display.setCursor(72, 16);

display.print("mg");

display.setCursor(0, 24);

display.print((int)(myIMU.gx));

display.setCursor(24, 24);

display.print((int)(myIMU.gy));

display.setCursor(48, 24);

display.print((int)(myIMU.gz));

display.setCursor(66, 24);

display.print("o/s");

display.setCursor(0, 32);

display.print((int)(myIMU.mx));

display.setCursor(24, 32);

display.print((int)(myIMU.my));

display.setCursor(48, 32);

display.print((int)(myIMU.mz));

display.setCursor(72, 32);

display.print("mG");

display.setCursor(0, 40);

display.print("Gyro T ");

display.setCursor(50, 40);

display.print(myIMU.temperature, 1);

display.print(" C");

display.display();

#endif // LCD

myIMU.count = millis();

digitalWrite(myLed, !digitalRead(myLed)); // toggle led

} // if (myIMU.delt_t > 500)

} // if (!AHRS)

else

{

// Serial print and/or display at 0.5 s rate independent of data rates

myIMU.delt_t = millis() - myIMU.count;

// update LCD once per half-second independent of read rate

if (myIMU.delt_t > 500)

{

if (SerialDebug)

{

Serial.print("ax = ");

Serial.print((int)1000 * myIMU.ax);

Serial.print(" ay = ");

Serial.print((int)1000 * myIMU.ay);

Serial.print(" az = ");

Serial.print((int)1000 * myIMU.az);

Serial.println(" mg");

Serial.print("gx = ");

Serial.print(myIMU.gx, 2);

Serial.print(" gy = ");

Serial.print(myIMU.gy, 2);

Serial.print(" gz = ");

Serial.print(myIMU.gz, 2);

Serial.println(" deg/s");

Serial.print("mx = ");

Serial.print((int)myIMU.mx);

Serial.print(" my = ");

Serial.print((int)myIMU.my);

Serial.print(" mz = ");

Serial.print((int)myIMU.mz);

Serial.println(" mG");

Serial.print("q0 = ");

Serial.print(*getQ());

Serial.print(" qx = ");

Serial.print(*(getQ() + 1));

Serial.print(" qy = ");

Serial.print(*(getQ() + 2));

Serial.print(" qz = ");

Serial.println(*(getQ() + 3));

}

// Define output variables from updated quaternion---these are Tait-Bryan

// angles, commonly used in aircraft orientation. In this coordinate system,

// the positive z-axis is down toward Earth. Yaw is the angle between Sensor

// x-axis and Earth magnetic North (or true North if corrected for local

// declination, looking down on the sensor positive yaw is counterclockwise.

// Pitch is angle between sensor x-axis and Earth ground plane, toward the

// Earth is positive, up toward the sky is negative. Roll is angle between

// sensor y-axis and Earth ground plane, y-axis up is positive roll. These

// arise from the definition of the homogeneous rotation matrix constructed

// from quaternions. Tait-Bryan angles as well as Euler angles are

// non-commutative; that is, the get the correct orientation the rotations

// must be applied in the correct order which for this configuration is yaw,

// pitch, and then roll.

// For more see

// http://en.wikipedia.org/wiki/Conversion_between_quaternions_and_Euler_angles

// which has additional links.

myIMU.yaw = atan2(2.0f * (*(getQ() + 1) * *(getQ() + 2) + *getQ() *

*(getQ() + 3)),

*getQ() * *getQ() + *(getQ() + 1) * *(getQ() + 1) - *(getQ() + 2) * *(getQ() + 2) - *(getQ() + 3) * *(getQ() + 3));

myIMU.pitch = -asin(2.0f * (*(getQ() + 1) * *(getQ() + 3) - *getQ() *

*(getQ() + 2)));

myIMU.roll = atan2(2.0f * (*getQ() * *(getQ() + 1) + *(getQ() + 2) *

*(getQ() + 3)),

*getQ() * *getQ() - *(getQ() + 1) * *(getQ() + 1) - *(getQ() + 2) * *(getQ() + 2) + *(getQ() + 3) * *(getQ() + 3));

myIMU.pitch *= RAD_TO_DEG;

myIMU.yaw *= RAD_TO_DEG;

// Declination of SparkFun Electronics (40°05'26.6"N 105°11'05.9"W) is

// 8° 30' E ± 0° 21' (or 8.5°) on 2016-07-19

// - http://www.ngdc.noaa.gov/geomag-web/#declination

myIMU.yaw -= 8.5;

myIMU.roll *= RAD_TO_DEG;

if (SerialDebug)

{

Serial.print("Yaw, Pitch, Roll: ");

Serial.print(myIMU.yaw, 2);

Serial.print(", ");

Serial.print(myIMU.pitch, 2);

Serial.print(", ");

Serial.println(myIMU.roll, 2);

Serial.print("rate = ");

Serial.print((float)myIMU.sumCount / myIMU.sum, 2);

Serial.println(" Hz");

}

#ifdef LCD

display.clearDisplay();

display.setCursor(0, 0);

display.print(" x y z ");

display.setCursor(0, 8);

display.print((int)(1000 * myIMU.ax));

display.setCursor(24, 8);

display.print((int)(1000 * myIMU.ay));

display.setCursor(48, 8);

display.print((int)(1000 * myIMU.az));

display.setCursor(72, 8);

display.print("mg");

display.setCursor(0, 16);

display.print((int)(myIMU.gx));

display.setCursor(24, 16);

display.print((int)(myIMU.gy));

display.setCursor(48, 16);

display.print((int)(myIMU.gz));

display.setCursor(66, 16);

display.print("o/s");

display.setCursor(0, 24);

display.print((int)(myIMU.mx));

display.setCursor(24, 24);

display.print((int)(myIMU.my));

display.setCursor(48, 24);

display.print((int)(myIMU.mz));

display.setCursor(72, 24);

display.print("mG");

display.setCursor(0, 32);

display.print((int)(myIMU.yaw));

display.setCursor(24, 32);

display.print((int)(myIMU.pitch));

display.setCursor(48, 32);

display.print((int)(myIMU.roll));

display.setCursor(66, 32);

display.print("ypr");

// With these settings the filter is updating at a ~145 Hz rate using the

// Madgwick scheme and >200 Hz using the Mahony scheme even though the

// display refreshes at only 2 Hz. The filter update rate is determined

// mostly by the mathematical steps in the respective algorithms, the

// processor speed (8 MHz for the 3.3V Pro Mini), and the magnetometer ODR:

// an ODR of 10 Hz for the magnetometer produce the above rates, maximum

// magnetometer ODR of 100 Hz produces filter update rates of 36 - 145 and

// ~38 Hz for the Madgwick and Mahony schemes, respectively. This is

// presumably because the magnetometer read takes longer than the gyro or

// accelerometer reads. This filter update rate should be fast enough to

// maintain accurate platform orientation for stabilization control of a

// fast-moving robot or quadcopter. Compare to the update rate of 200 Hz

// produced by the on-board Digital Motion Processor of Invensense's MPU6050

// 6 DoF and MPU9150 9DoF sensors. The 3.3 V 8 MHz Pro Mini is doing pretty

// well!

display.setCursor(0, 40);

display.print("rt: ");

display.print((float)myIMU.sumCount / myIMU.sum, 2);

display.print(" Hz");

display.display();

#endif // LCD

myIMU.count = millis();

myIMU.sumCount = 0;

myIMU.sum = 0;

} // if (myIMU.delt_t > 500)

} // if (AHRS)

}

本代码已经上传至github,可以去下载使用github地址

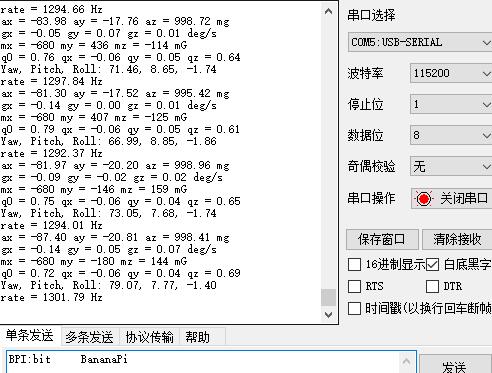

下面是烧录本程序后,串口返回的信息: